Robot Marker

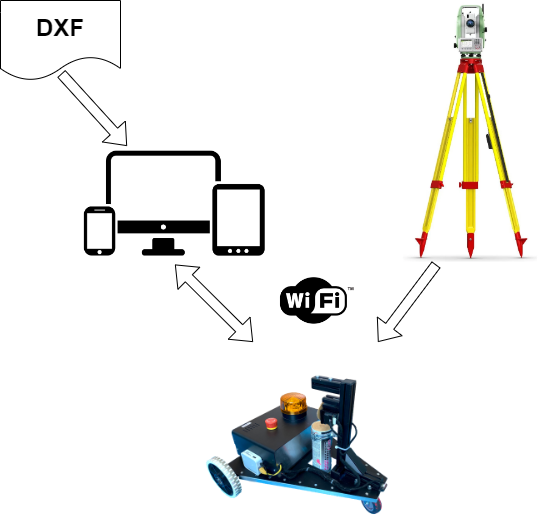

Robot for automatic positioning of magnets for coordinate network.

- Autonomous operation

- Web-based user interface

- Platform support – Win, iOS, Android

- Time saving compared to manual use

- Marking accuracy of 2 mm

- Lower weight

- Ready to use in 2 minutes

- Easy to use

Work packages

The development of a robot is a complex process that involves a variety of disciplines and areas of expertise. Here is a detailed description of the various steps performed in the development of the marking robot, including concept definition, implementation of control in the Robot Operating System (ROS2), definition and implementation of communication with a geodetic total station, development of the user interface and complete system development (software, mechanical hardware, electrical hardware):

1. concept definition

Requirements analysis:

- Identify the specific requirements and objectives of the robot.

- Definition of the operating environment and the tasks to be solved.

- Definition of functional and non-functional requirements.

Feasibility study:

- Technological feasibility: Investigation of available technologies and components.

- Economic feasibility: cost analysis and budget planning.

- Time feasibility: Creation of a schedule and milestones.

System architecture:

- Rough draft of the system architecture, including hardware and software components.

- Definition of the communication interfaces and interactions between the components.

2. implementation of the controller in the Robot Operating System (ROS2)

Setting up the development environment:

- Installation and configuration of the ROS2 development environment.

- Selection of suitable ROS2 distributions based on the project requirements.

Modeling of the robot:

- Creation of a URDF (Unified Robot Description Format) model to describe the physical structure of the robot.

- Simulation of the robot in Gazebo.

Development of the control algorithms:

- Implementation of basic control for drives and sensors.

- Use of ROS2 nodes for modular structuring of the control software.

- Implementation of the path planning algorithms.

Test and validation:

- Execution of tests in the simulation environment and in real operation.

- Verification of the control algorithms and adjustments based on the test results.

3. definition and implementation of communication with the geodetic total station

Interface definition:

- Analysis of the communication protocols of the geodetic total station.

- Definition of the communication protocol

Implementation of the communication interface:

- Development of ROS2 nodes for communication with the total station.

- Processing of the received data and integration into the robot’s control algorithms.

Calibration and synchronization:

- Calibration of the total station and the robot to ensure precise position data.

- Synchronization of time stamps to ensure data integrity.

Test and validation:

- Test of the communication interface in the real environment.

- Verification of the accuracy and reliability of the position data.

4. development of the user interface

Requirements analysis:

- Definition of user requirements and expectations.

- Determining the functions and design of the user interface.

Prototyping:

- Creating mockups and wireframes of the user interface.

- Conducting user studies and obtaining feedback.

Implementation:

- Development of the user interface using JScript and Angular technologies

- Integration of the user interface with the ROS2 control software.

Testing and validation:

- Conducting usability tests with end users.

- Customization based on user feedback.

5. complete system development (software, mechanical hardware, electrical hardware)

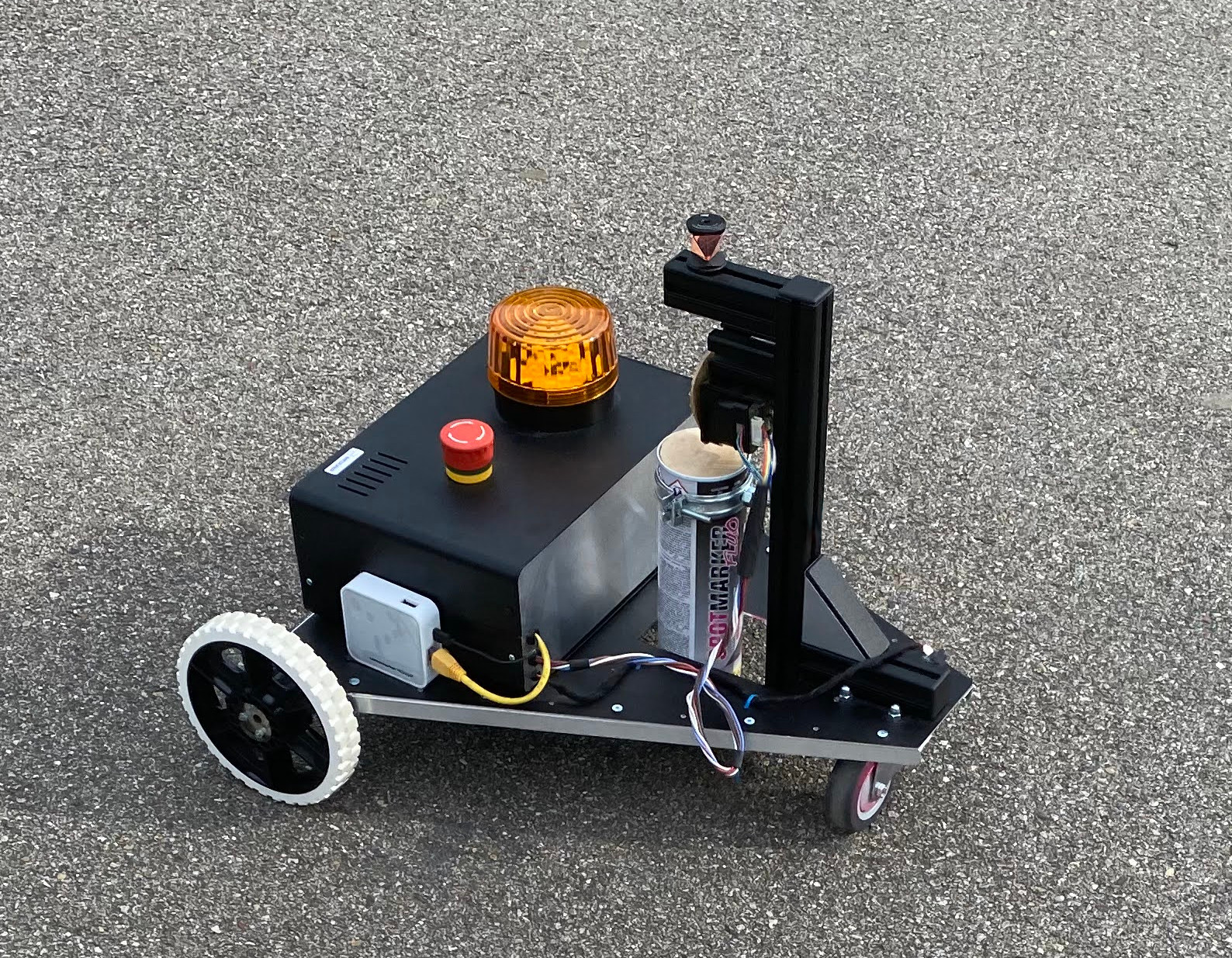

Mechanical hardware development:

- Detailed design and construction of the mechanical components of the robot.

- Manufacturing and assembly of the mechanical parts.

- Performance of load tests and adjustments.

Electrical hardware development:

- Designing the electronic circuit diagrams and PCB layouts.

- Production and assembly of the circuit boards.

- Integration of sensors, actuators and control units.

Software development:

- Integration of all software modules (control algorithms, communication interfaces, user interface).

- Carrying out extensive tests and debugging.

- Optimization of the software in terms of performance and reliability.

System integration:

- Assembling all components (mechanical, electrical and software).

- Carrying out system tests to check overall functionality.

- Calibration and fine-tuning of the entire system.

Validation and verification:

- Carrying out extensive tests in the target environment.

- Ensuring that all requirements are met and that the robot functions reliably.

Documentation and handover:

- Preparation of technical documentation and user manuals.

- Training of end users and handover of the system to the customer.